Quality of

components

and attention to details

Development of customized projects

based on customer needs

50 years

of experience

in metal packaging

Quality of components

and attention to details

Customized Projects Development

based on customer needs

50 years of experience

in metal packaging

We are at the service of the metal packaging industry

Pack End Engineering S.r.l. is specialized in research, styling and achievement of Packaging, movement systems. We are dealing in this field for over 30 years and can provide you most suitable solution in base of your economical and tecnical demand.

Pack End Engineering S.r.l. company is know on a worldwide scale for reliability, competence and professionalism. Our staff is efficient and caring to client’s demand to guarantee an high level of Product quality.

Our Pluses

50 years of experience

in metal packaging

Development of customized projects based on customer needs

Component quality

and attention to details

We are at the service

of the metal packaging industry

Study and Design

Thanks to the experience accumulated over the years, Pack End offers a study and design service following the customer's needs and proposing innovative solutions to achieve maximum system optimization.

Construction and installation

We take care of systems realization with attention and dedication, personally taking care of their installation on site, always paying attention to new technologies on the market.

After-sales assistance

We guarantee a fast and efficient customer service system for any need on the systems installed.

ENDMAKING – CANMAKING

We are at the service

of the metal packaging industry

Study and Design

Thanks to the experience accumulated over the years, Pack End offers a study and design service following the customer's needs and proposing innovative solutions to achieve maximum system optimization.

Construction and installation

We take care of systems realization with attention and dedication, personally taking care of their installation on site, always paying attention to new technologies on the market.

After-sales assistance

We guarantee a fast and efficient customer service system for any need on the systems installed.

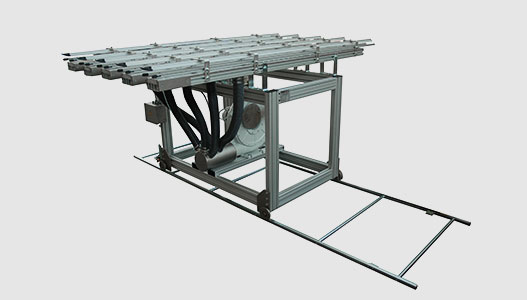

Magnetic and air conveyors

products

We study and manufacture magnetic and air conveyors

for any size and format.

Pin Hole Detector

The new Pack End Engineering s.r.l. Pin Hole Detector is an extremely sensitive photoelectric device with high signal conversion efficiency and optimum response time. This Pinhole detector is particulery suitable for the detection of very small holes in moving strips of steel or other materials.

This device is capable of detecting holes having a minimum area of 0.025mm2 (hole ø 0.001”).

The macine is ideally installed on coil cutting lines or special sheet inspection lines to guarantee a top quality inspection service.

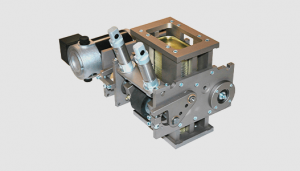

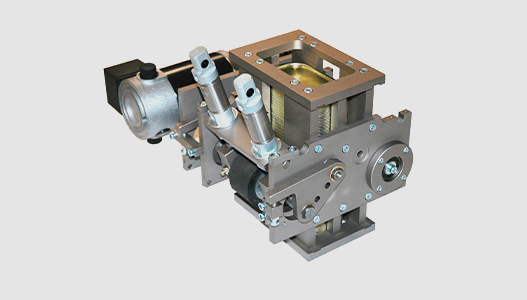

Gap Control (ROLL FEEDER SYSTEM)

One of the most important problems that can happen during feeding of EOE conversion press, seamer and generally all down stackers is the control of the ends level and the weight on the screws.

It always happened to use precarious systems very difficult to control and consequently loads act of down stackers roller in negative way causing slowdown in the production and difficulties on the regulation of down stackers.

The Roll Feeder system allow to fix the problem thanks to employment of special rolls that measure out feeding on the downstream machine, controlling the load and level on the down stackers. The higher load that the Roll Feeder system can support can achieve substantial height, achieving high feeding speed (1200 ends/minute).

The Roll Feeder system is just successfully implemented in various EOE and OT production facilities. In addition to the standard circular ends it is used for different shapes, including rectangular and oval. It can work with both TFS/BS and ALU material.

Wrapper

Automatic machine for wrappingandpackaging lids of various sizes and types in shrink plastic film.

Unwrapper

Automatic machine for removing heat-shrink plastic film from lids of various sizes and types.

Bagger

Semi-automatic machine for counting and forming groups of lids of various sizes and types to be bagged manually.

Power supply and lid distribution system

Pack End Engineering has always produced power systems for seamers both in the General line sector and in the food sector.

Air and vacuum transport

We create transport systems both with blowing air and vacuum for boxes and lids.

Magnetic Transport

We create different types of transport designed according to the customer’s layout needs.

End line balancers (Buffer)

Where a small production balancing system is required, we can create an adequate solution based on the autonomy required by the customer.

Magnetic Pulleys

We produce different types of magnetic pulleys for the transport, overturning and re-stacking of the lids.

Connection cages

We make connection cages in stainless steel to connect various types of machines with our transports (seamers, presses, wrappers, etc.)

PIN HOLE DETECTOR

Particolarmente adatto per la individuazione di buchi molto piccoli in strisce in movimento in acciaio od altri materiali.

Dettagli →

Il sistema Roll Feeder, permette di risolvere il problema, grazie all’utilizzo di rulli speciali che dosano l’alimentazione sulla macchina a valle, controllando il carico ed il livello sullo sfogliatore.

Dettagli →

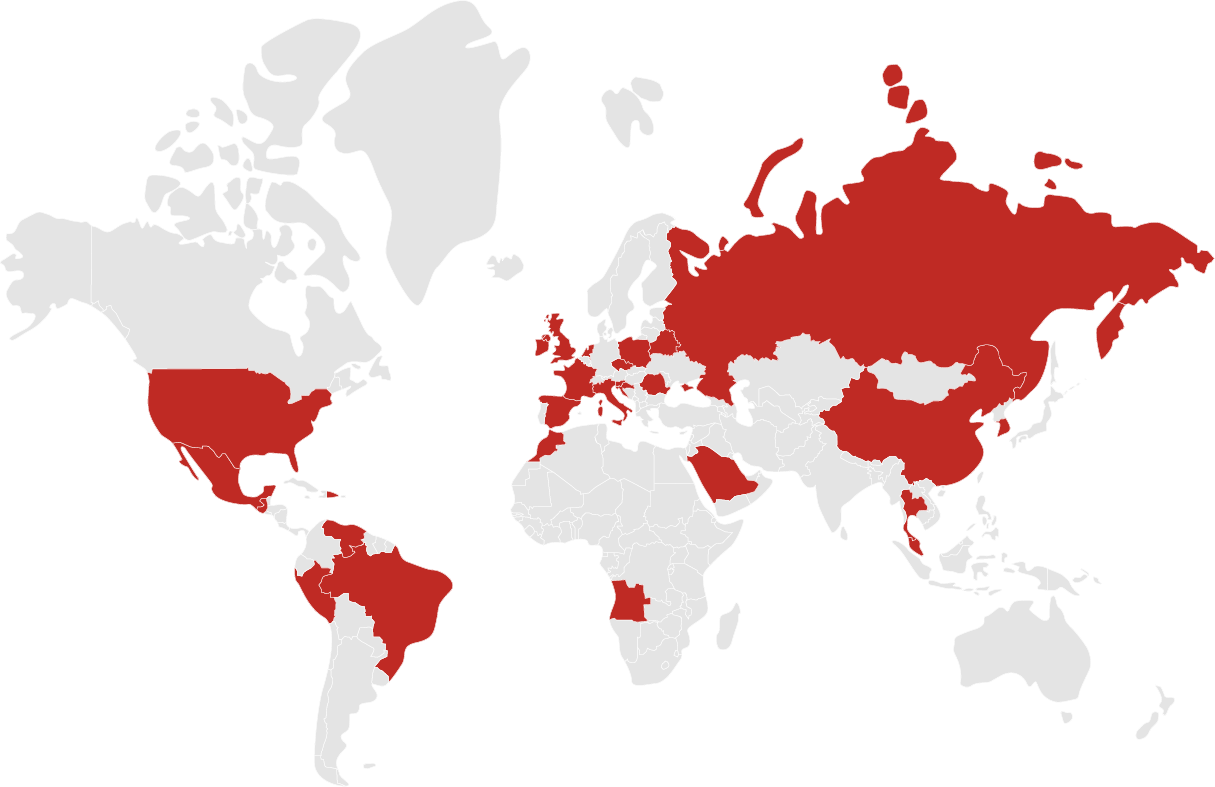

Packend in the world

You can find our plants in the following countries:

Italy, France, Great Britain, Spain, Slovenia, Croatia, Czech Republic, Poland, Romania, Belarus, Russia, Holland, Morocco, Angola, Saudi Arabia, Guatemala, Peru, Venezuela, Puerto Rico, USA, Mexico, Brazil, Malaysia, China , Thailand, South Korea.